Ventilation systems from TK ENERGIA INDUSTRY:

Our systems solve problems such as:

If you are struggling with any of these problems, leave a contact for yourself, we will get back to you and help you solve it!

Industries we have experience in:

If your industry is not listed here, but you have one of the problems we have listed,

call +48 602 687 466 and we will help you solve it!

Our ventilation systems are based on TK HELI destratification units and control cabinets manufactured in Poland.

Each system is individually selected for the building in which it is to be installed, so that it effectively solves the existing problem.

When designing a ventilation system, we consider many factors, including

The HVLS TK HELI fans used in the systems are destratification fans that operate on the rotation of low-speed propellers and low power consumption.

TK HELI fans move, circulate and mix large volumes of air throughout the room, improving air quality and creating the right microclimate in the rooms.

HVLS stands for High Volume Low Speed.

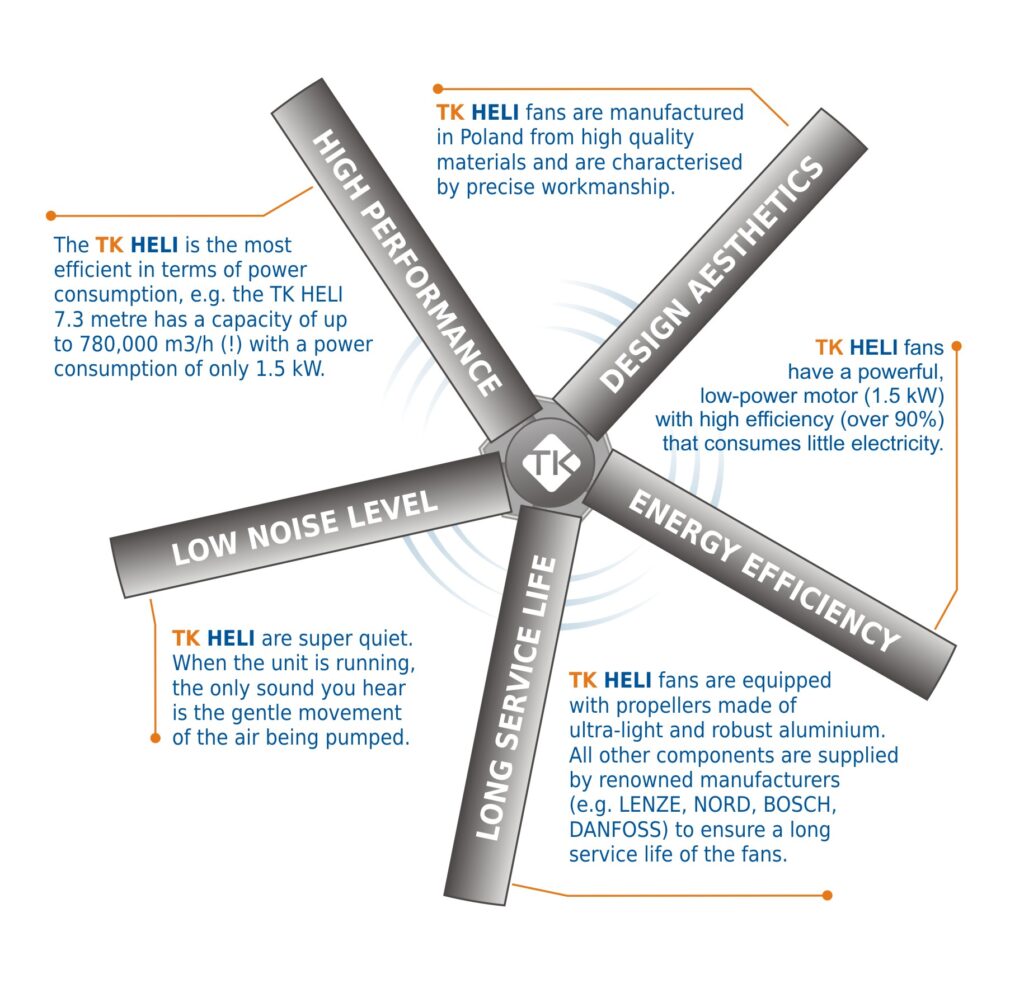

Key features of TK HELI fans:

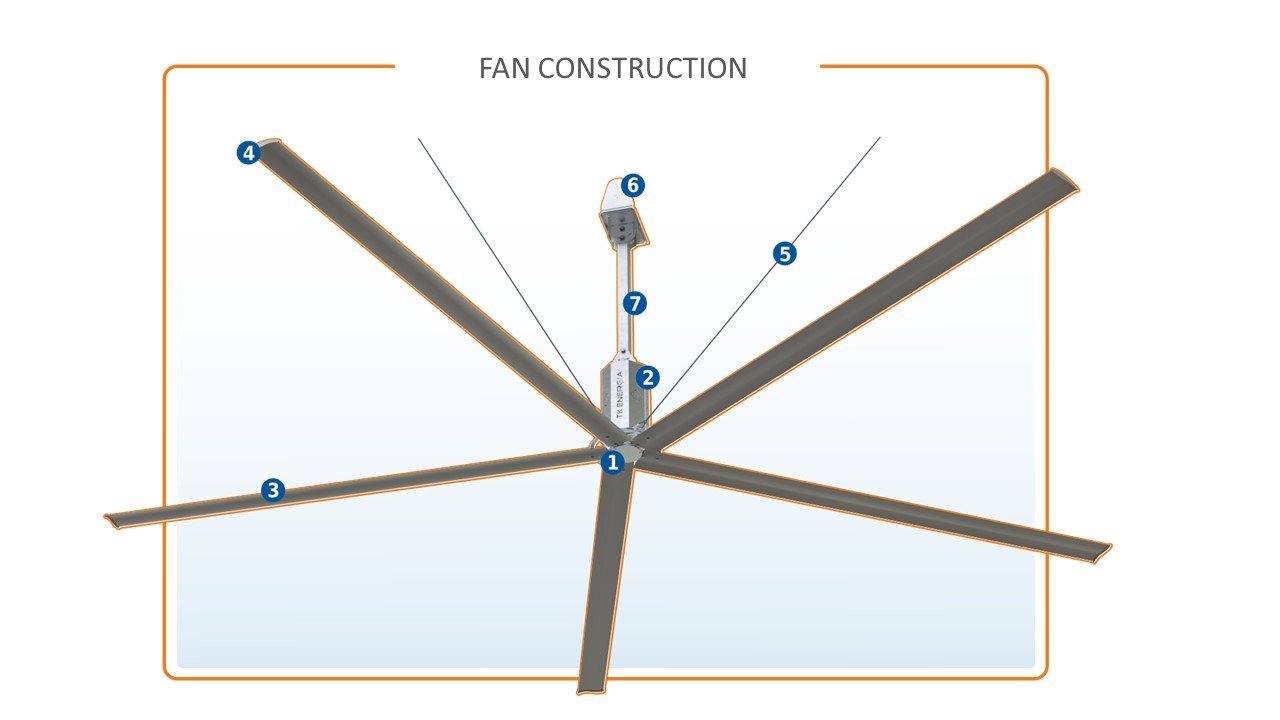

Main core – supporting element for motor and blades

Motor – the 'heart’ of the fan, a motor with inverter

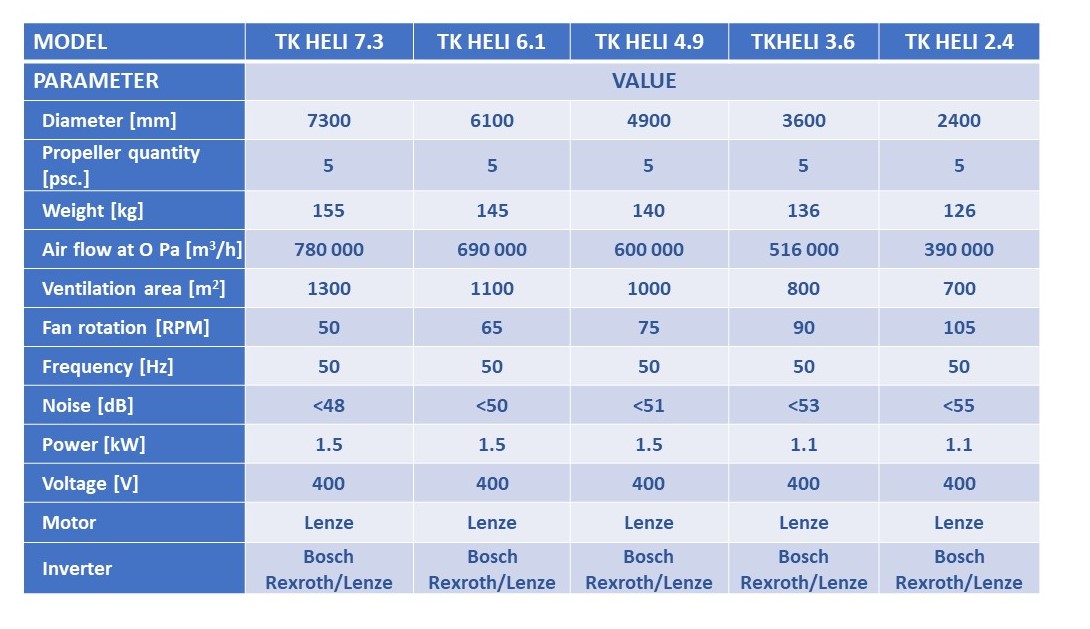

Technical specifications of available TK HELI models:

Efficiency of TK HELI fans:

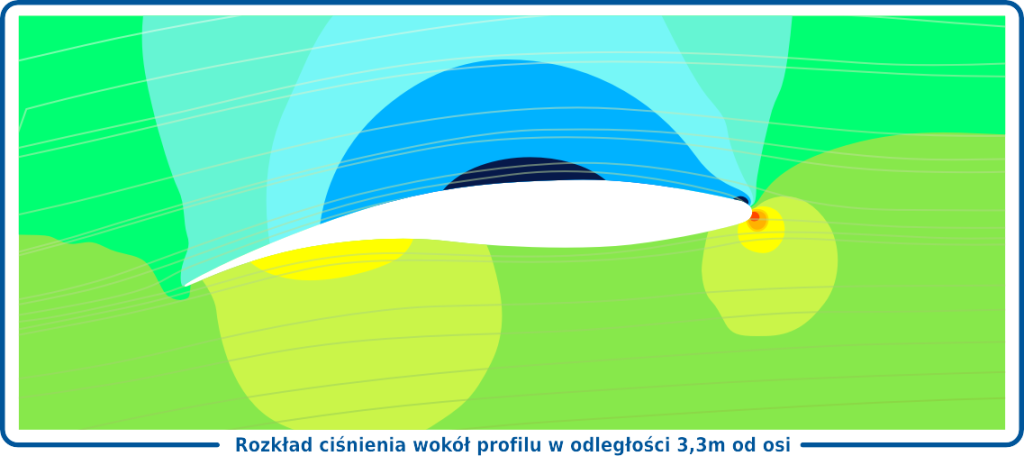

TK HELI fans are designed to ventilate industrial facilities effectively and safely. Polish and European engineers have ensured that the fans do not overload roof structures and have researched how the air should be distributed so that the fans ventilate rooms as efficiently as possible.

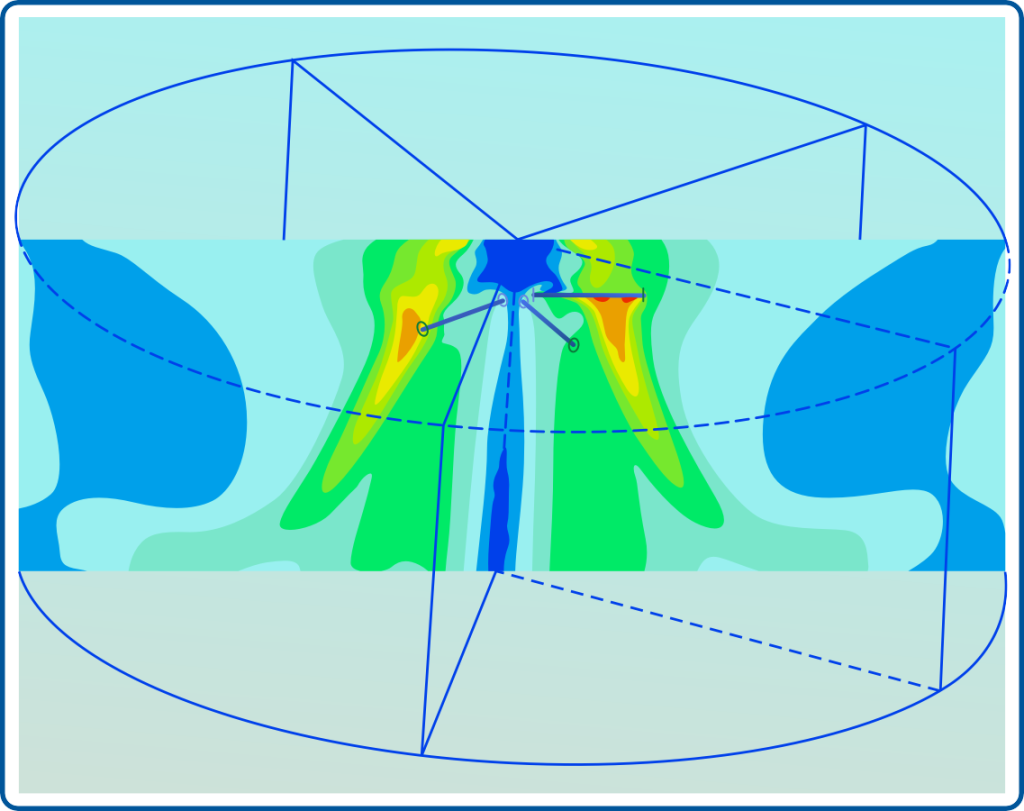

The figure shows the pressure distribution around the fan profile. The blue area in the middle of the top of the profile indicates the correct location of the negative pressure (over the entire top), while the yellow area at the bottom indicates the location of the positive pressure.

The figure shows the velocity distributions across the model section. It can be seen that there is a concentration of velocity at the end of the blade due to an increase in circumferential velocity as the blade moves away from the rotor axis. This is a normal phenomenon for a blade with a constant profile along its length.

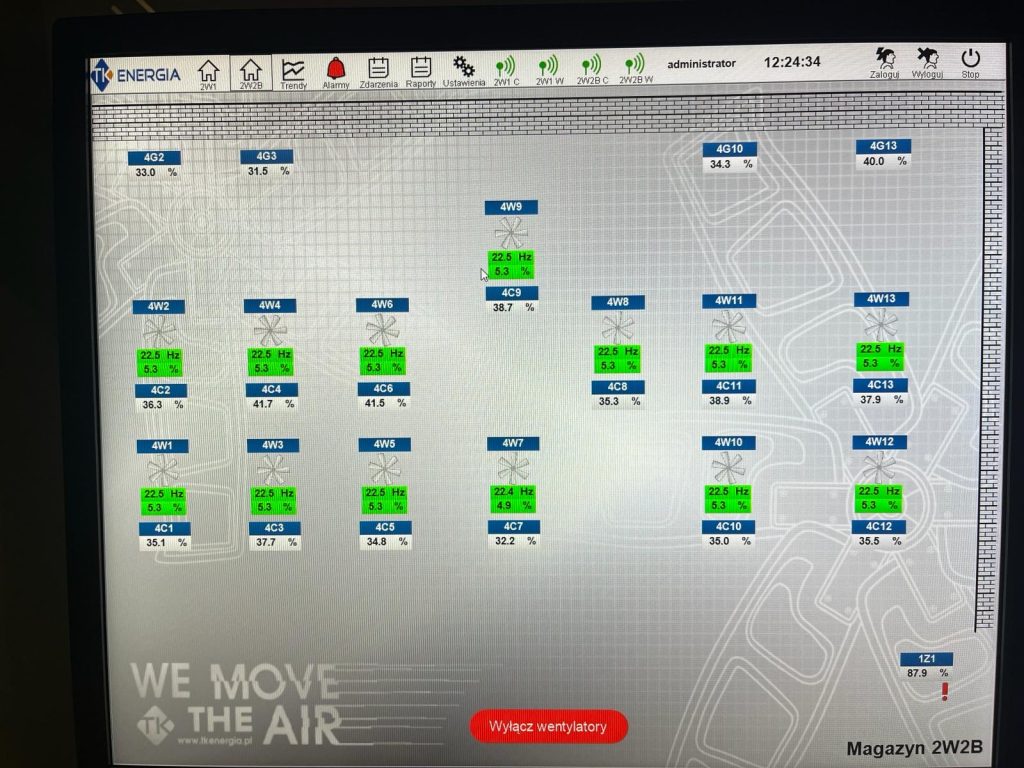

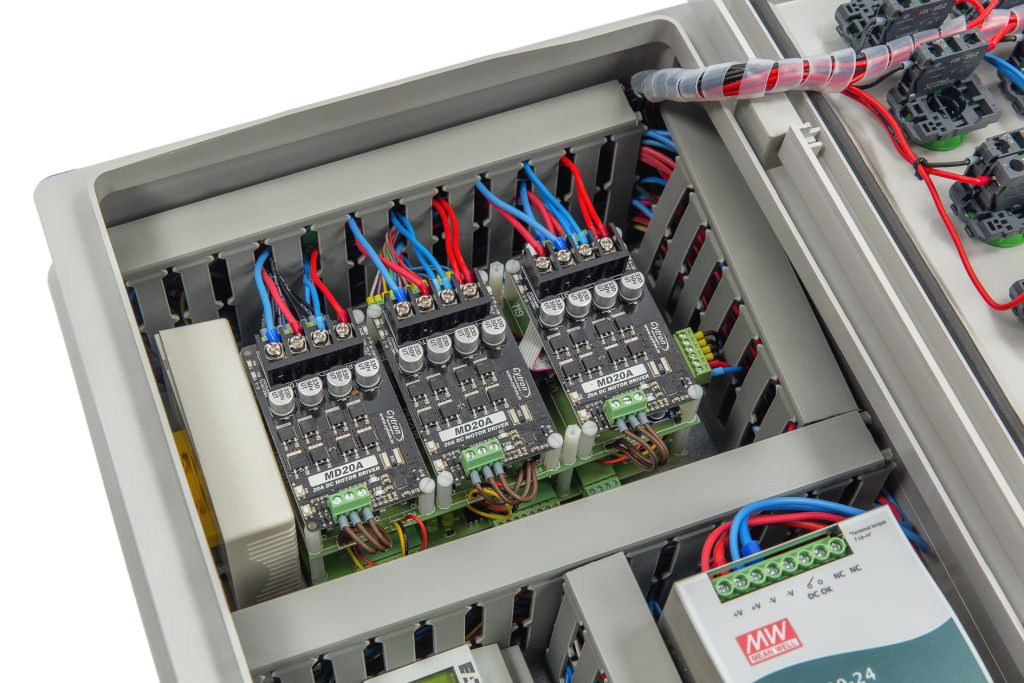

Control cabinets and automation of the ventilation process

We manufacture control cabinets for HELI’s TK fans, which enable full automation of the fan control process. The control cabinets are responsible for the entire ventilation process, from switching on the fans to monitoring the set parameters and switching off the system.

Automation makes the ventilation process easier and more efficient by controlling the temperature and humidity in the facility. Automation saves valuable time, minimises the risk of error and reduces heating costs.

Ventilation control systems are tailored to the needs of the customer, the facility in which the system is to be installed and the equipment to be included in the system.

Feedback from our customers

Contact